Gibson ES335 Jazz Guitar PLANS - Full Scale - How to Build Review

Gibson ES335 Jazz Guitar PLANS - Full Scale - How to Build Feature

- full scale plans to build the Gibson es335 jazz guitar

Gibson ES335 Jazz Guitar PLANS - Full Scale - How to Build Review

Pyle-Pro PVAMP120 1x12 Guitar Amplifier Cabinet Review

Gibson J-45 Standard Acoustic-Electric Guitar, Antique Natural Review

The Workhorse.

Grover's original Rotomatic tuners are an engineering marvel, with abundant style and performance exactly suited for the J-45. With a gear ratio of 14:1, the Rotomatics deliver precision tuning in a durable housing that provides maximum protection for the gear and string post. All moving parts are cut for exact meshing, eliminating the possibility of slippage. A countersunk tension screw lets players regulate the tuning tension to any degree. A special lubricant inside the gear box provides smooth and accurate tuning stability.

Body Tonewoods (back, sides and top)

The top of the J-45 is made from AA-grade Sitka spruce, while the back and sides are constructed from pattern grade Honduras mahogany, giving the J-45 its world renowned full, balanced expression, warm bass, and excellent projection. Selecting the right wood, and the formula to dry it out, are two of the most central procedures to Gibson's guitar-building process. Beginning with its first catalog in 1903, Gibson has assured its customers that every guitar would be built using woods with "the most durable, elastic, and sonorous qualities," and today's guitars from Gibson Acoustic are no different.

Pickguard

The pickguard for the J-45 is Gibson's standard plain tortoise tear drop shape, which has been used on the J-45 since its introduction in 1942. As with all of Gibson's pickguards, the coloring and binding are all done by hand.

Rosette

A rosette is the beautiful, hand-crafted circle around the soundhole, and can be one of the most ornamental elements of any acoustic guitar. It is also one of the most subtle and complicated woodworking decorations on any acoustic guitar. The rosette on the J-45 is a simple single-ring rosette consisting of three-ply binding, adding a stylish, understated elegance to the J-45 Standard.

Rosewood Fingerboard with Rolled Edges and Dot Inlays

The fingerboard of Gibson's J-45 is constructed from the highest grade rosewood on earth, which is personally inspected and qualified by Gibson's team of skilled experts before it enters the Gibson factories. The resilience of this durable wood makes the fingerboard extremely balanced and stable, and gives each chord and note unparalleled clarity and bite. The J-45's dot inlays are made of genuine mother of pearl, measuring approximately 1/4-inch in diameter, and are inserted into the fingerboard using a process that eliminates gaps. The fingerboard also sports a rolled edge--instead of the usual right angle where the fingerboard surface meets the neck, Gibson Acoustic's rolled edges are slightly beveled for an extremely smooth and comfortable feel, enhancing the playability of the J-45.

L.R. Baggs Element Active Acoustic Pickup System

Gibson Acoustic's J-45 comes equipped with the popular Element Active Acoustic Pickup System from L.R. Baggs, which features a low-profile undersaddle element--or transducer--that's proven more stable and durable than many standard ribbon-type pickups. Combined with an onboard preamp with an unobtrusive volume control mounted just inside the soundhole, the Element delivers performance not previously attainable from an undersaddle pickup. Its sleek and effective design removes unnecessary internal components to enhance the coupling between the pickup and the guitar, and improve the sensitivity of the transducer for a robust, lively, and natural acoustic sound with excellent dynamics and delicate high end. The Element works with a standard 9V battery, which is housed inside the guitar in L.R. Bagg's new "Battery Bagg."

Bracing

Every acoustic guitar made by Gibson features hand-scalloped, radiused top bracing inside the body, a feature normally found only in limited run, hand-made guitars. By scalloping each brace by hand, the natural sound of the acoustic is focused more toward the center of the body, enhancing the instrument's sound projection. The J-45 features a variation of Gibson's "X" bracing pattern situated behind the soundhole, with a set of tall and thin braces for the back, and scalloped tall and thin braces for the top. This legendary bracing design delivers a balanced expression, with punchy, deep lows, warm mids, and clear, crisp highs. When pushed for more volume, the J-45 projects a natural compression, which helps it blend nicely with any accompaniment.

Tapered Dovetail Neck Joint

The dovetail neck joint is one of the oldest--and best--ways of securely joining the neck to the body of a guitar. It is also a complex and expensive neck joint to build, but the result is a tight, locking connection that supports the neck at the proper neck-pitch angle, allowing the body and neck to become one solid piece of resonating wood, with no metal to impede vibration. This process is done entirely by hand, requiring patience and skill.

Radius Top

The top of many "flat-top" guitars are under a lot of stress from the pull of the strings, which can eventually compromise the top. So, while most acoustic guitars are true "flat-top" guitars, all of the acoustics produced by Gibson in Bozeman, Montana have a radiused, or "tuned" top. Instead of being perfectly flat, a radiused or "tuned" top is raised slightly, and a special instrument is used to shape the top braces to the radius of the top. This process adds tension and strengthens the top, creating a less stressful joint where the top meets the sides and reducing the stresses of string pull. It also results in a "speaker cone" effect that maximizes sound projection, adding a significant boost to mid-range levels for a more balanced acoustic tone.

Nitrocellulose Finish

Applying a nitrocellulose finish to any Gibson acoustic guitar--including the J-45 Standard--is one of the most labor-intensive elements of the guitar-making process. Unlike the polyurethane finishes used by many guitar manufacturers, a nitrocellulose lacquer finish is porous when cured, allowing the wood to naturally "breathes and mature. Microscopically thin, the finish on a Gibson acoustic guitar first requires seven main coats of nitrocellulose lacquer. After drying overnight, the initial seven coats are then level sanded and given two additional coats. Left to dry for five additional days, the finish is then wet sanded and buffed to its final glass-like sheen. The time-consuming nature of applying a nitro finish has been employed ever since the first Gibson guitar was swathed with lacquer back in 1894. Why? For starters, a nitro finish means there is less interference with the natural vibration of the instrument, allowing for a purer tone. It's also a softer finish, making it easily repairable. You can touch up a scratch or ding on a nitro finish, but you can't do the same on a poly finish.

Body Binding

In general, a guitar's binding serves as a cosmetic feature, adding a subtle elegance to any Gibson acoustic while hiding the joints between the top, back, and sides, and helping to protect the guitar's body from any nicks or dings. But to see the process of putting the binding on a Gibson acoustic is to really appreciate the effort and attention put into each instrument. After the body has been glued together, the excess from the top and back are trimmed off and a groove is cut for the binding. The binding is then glued on and held on to the body using tape, and left to dry. When the tape comes off, any excess glue is removed and the body is moved into the next phase of production. It has been done the same way for over 100 years, and is a fundamental part of Gibson Acoustic's rich guitar-making history.

The J-45 has been Gibson’s top-selling acoustic guitar for years. Nicknamed “The Workhorse” and first introduced in 1942, Gibson’s most popular acoustic is now the icon of its round-shoulder, dreadnought line, world renowned for its full, balanced expression, warm bass, and excellent projection. Subtle changes to the bracing of its predecessor—the J-35—made Gibson’s J-45 one of most technically advanced guitars of its time.

Shine Wt440 Bigsby Custom Lp Review

Gibson J-185 EC Acoustic-Electric Guitar, Rosewood Review

Gibson Les Paul Custom 5-Ply Pickguard with Screws Black Review

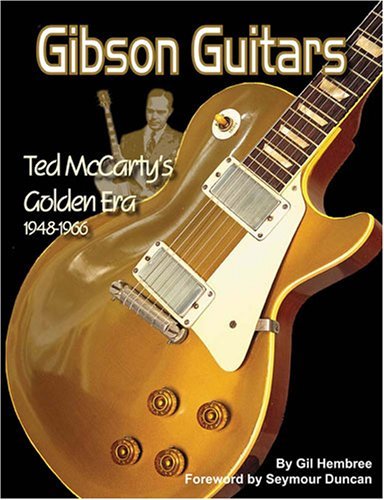

Gibson Guitars - Ted McCarty's Golden Era: 1948-1966 - Book Review

Epiphone SST Studio Solid-Body Acoustic-Electric Guitar, Ebony Review

TKL 7826 SG Style Electric Guitar Case Review

Bigsby B5 Vibrato Kit - Flat Top Solid Body (Gibson SG, Flying V, Exlporer, Firebird) Review

For solid body Gibson (Gibson SG, Flying V, Exlporer, Firebird) guitars, the B5 Bigsby bridge is for manually creating a true vibrato.

The only true vibrato is to change the tone above and below the normal pitch.

Bigsby continues to manufacture vintage-style guitar parts including vibratos and bridges using the same hand-made methods prescribed by founder Paul Bigsby half a century ago. Six hand assembled vibrato models are available with the Bigsby name. The tailpieces continue to be used as original equipment on guitars by many major manufacturers.

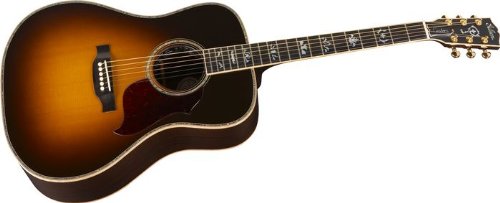

Gibson Songwriter Deluxe Custom Acoustic-Electric Guitar, Vintage Sunburst Review

The finest offering from the Songwriter family of acoustics.

Gold Grover Rotomatic Tuners

Grover's original Rotomatic tuners are an engineering marvel, with abundant style and performance exactly suited for the Songwriter Deluxe Custom. With a gear ratio of 14:1, the Rotomatics deliver precision tuning in a durable housing that provides maximum protection for the gear and string post. All moving parts are cut for exact meshing, eliminating the possibility of slippage. A countersunk tension screw lets players regulate the tuning tension to any degree. A special lubricant inside the gear box provides smooth and accurate tuning stability.

Pickguard

The pickguard on the Songwriter Deluxe Custom is a custom line design made from Tortec. As with all of Gibson's pickguards, the coloring, inlay, and binding are all done by hand.

Tapered dovetail neck joint allows the body and neck to become one solid piece of resonating wood. |

Double-ring rosette with an abalone-filled middle. |

Distinctive mother of pearl fingerboard and headstock inlays. |

Rosette

A rosette is the beautiful, hand-crafted circle around the soundhole, and can be one of the most ornamental elements of any acoustic guitar. It is also one of the most subtle and complicated woodworking decorations on any acoustic guitar. The rosette on the Songwriter Deluxe Custom is one of Gibson's finest. It is a double-ring rosette with an abalone-filled middle, with both outer rings consisting of six-ply binding, adding a stylish, understated elegance to the Songwriter line.

Ebony Fingerboard with Rolled Edges and New Deluxe Custom Inlays

The fingerboard of Gibson's Songwriter Deluxe Custom is constructed from the highest grade ebony on earth, which is personally inspected and qualified by Gibson's team of skilled experts before it enters the Gibson factories. The resilience of this durable wood makes the fingerboard extremely balanced and stable, and gives each chord and note unparalleled clarity and bite. The fingerboard inlays of the Songwriter Deluxe Custom are a completely new design made of genuine mother of pearl, and inserted into the fingerboard using a process that eliminates gaps and doesn't require the use of fillers. The fingerboard also sports a rolled edge--instead of the usual right angle where the fingerboard surface meets the neck, Gibson Acoustic's rolled edges are slightly beveled for an extremely smooth and comfortable feel, enhancing the playability of the Songwriter Deluxe Custom.

Body Tonewoods

The body design of the Songwriter Deluxe Custom is known as a small dreadnought. The top is made from AA-grade Sitka spruce, while the back and sides are constructed from rosewood, giving the Songwriter a balanced, warm tone with clear lows and solid treble registers. Selecting the right wood, and the formula to dry it out, are two of the most central procedures to Gibson's guitar-building process. Beginning with its first catalog in 1903, Gibson has assured its customers that every guitar would be built using woods with "the most durable, elastic, and sonorous qualities," and today's guitars from Gibson Acoustic are no different.

Fishman Aura Pro Acoustic Pickup System

Gibson's Songwriter Deluxe Custom comes equipped with a built-in Fishman Ellipse Aura electronics package, which combines Fishman's most sophisticated onboard preamp design with the power of the popular Aura Acoustic Imaging Technology. The result is acoustic sound that is exceptionally accurate and true to life. Already loaded onto the system are four images that best match the instrument's natural tonal characteristics. You can make adjustments to any of them using the system's Pickup/Image Blend or Volume controls, or use the switchable Natural I and Natural II low frequencies for tone shaping. You can also control feedback with the Phase switch and automatic Anti-Feedback device control. The pickup's ergonomic soundhole-mounted design puts slider controls at your fingertips so you can maintain a natural playing position at all times. The Fishman Ellipse Aura is used by such noted musicians as Brad Paisley, Pete Townshend and Travis Tritt.

Bracing

Every acoustic guitar made by Gibson features hand-scalloped, radiused top bracing inside the body, a feature normally found only in limited run, hand-made guitars. By scalloping each brace by hand, the natural sound of the acoustic is focused more toward the center of the body, enhancing the instrument's sound projection. The bracing pattern inside the Songwriter Deluxe Custom is based on the design used for Gibson's celebrated Advanced Jumbo models of the 1930s, consisting of a wider "X" pattern that allows the top to vibrate more freely and push the sound toward the soundhole. The result is an instrument that delivers incredible response, and a superior dynamic range with balanced, warm tones, clear lows, and solid treble registers.

Tapered Dovetail Neck Joint

The dovetail neck joint is one of the oldest--and best--ways of securely joining the neck to the body of a guitar. It is also a complex and expensive neck joint to build, but the result is a tight, locking connection that supports the neck at the proper neck-pitch angle, allowing the body and neck to become one solid piece of resonating wood, with no metal to impede vibration. This process is done entirely by hand, requiring patience and skill.

Radius Top

The top of many "flat-top" guitars are under a lot of stress from the pull of the strings, which can eventually compromise the top. So, while most acoustic guitars are true "flat-top" guitars, all of the acoustics produced by Gibson in Bozeman, Montana have a radiused, or "tuned" top. Instead of being perfectly flat, a radiused or "tuned" top is raised slightly, and a special instrument is used to shape the top braces to the radius of the top. This process adds tension and strengthens the top, creating a less stressful joint where the top meets the sides and reducing the stresses of string pull. It also results in a "speaker cone" effect that maximizes sound projection, adding a significant boost to mid-range levels for a more balanced acoustic tone.

Nitrocellulose Finish

Applying a nitrocellulose finish to any Gibson acoustic guitar--including the Songmaker Deluxe Standard--is one of the most labor-intensive elements of the guitar-making process. Unlike the polyurethane finishes used by many guitar manufacturers, a nitrocellulose lacquer finish is porous when cured, allowing the wood to naturally "breathe" and mature. Microscopically thin, the finish on a Gibson acoustic guitar first requires seven main coats of nitrocellulose lacquer. After drying overnight, the initial seven coats are then level sanded and given two additional coats. Left to dry for five additional days, the finish is then wet sanded and buffed to its final glass-like sheen. The time-consuming nature of applying a nitro finish has been employed ever since the first Gibson guitar was swathed with lacquer back in 1894. Why? For starters, a nitro finish means there is less interference with the natural vibration of the instrument, allowing for a purer tone. It's also a softer finish, making it easily repairable. You can touch up a scratch or ding on a nitro finish, but you can't do the same on a poly finish.

With its abalone trim and distinctive mother of pearl fingerboard and headstock inlays, the new 2009 Songwriter Deluxe Custom is the finest offering from Gibson's Songwriter family of acoustics. It is considered one of the world's finest sounding square-shouldered acoustics, crafted to reflect simple and sophisticated elegance.

MIJ Tremolo Arm Caps for Fender Japan Metric Mint Green Review

Gibson Burstbucker Type 3 Humbuker Review

MIJ Guitar Pots Liner 500K 16mm Mini-Dime-Size Review

Gibson Custom B.B. King Lucille Gem Series Ruby Electric Guitar Ruby Red Review

MIJ Customized Speed Knob Set 4pc +Toggle knob Metric White Review